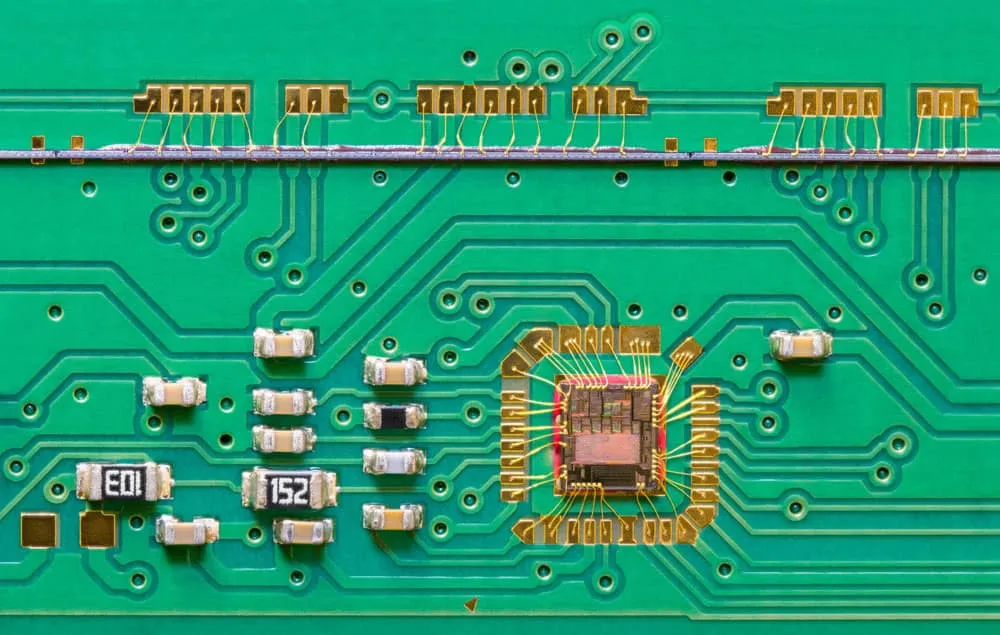

PCB Assembly Machine

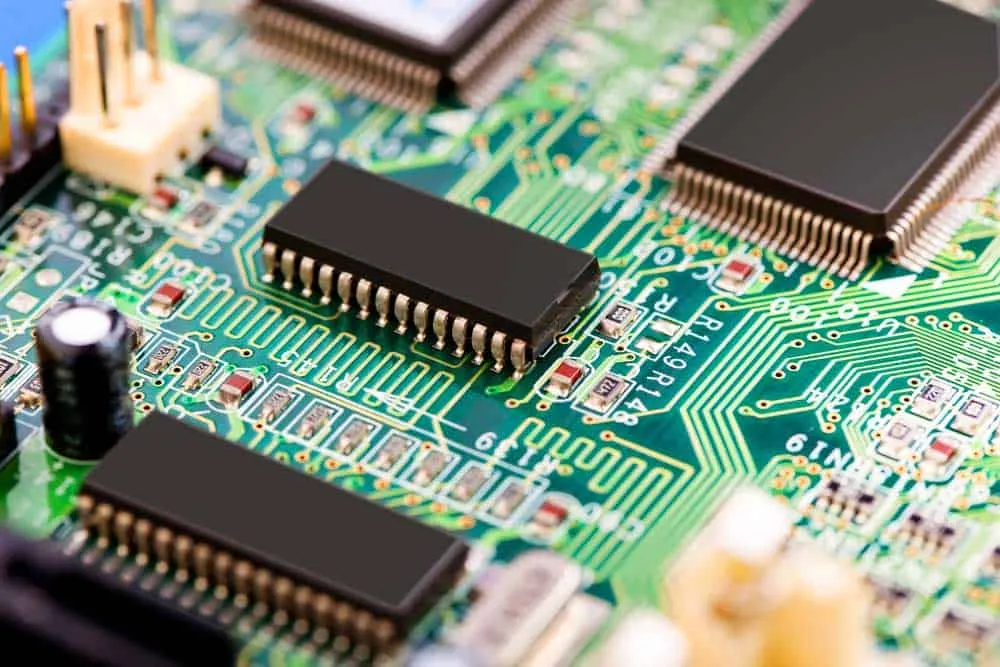

So assemblers need high-tech PCB assembly machine to mount and weld components on the board to make the circuit function as required.

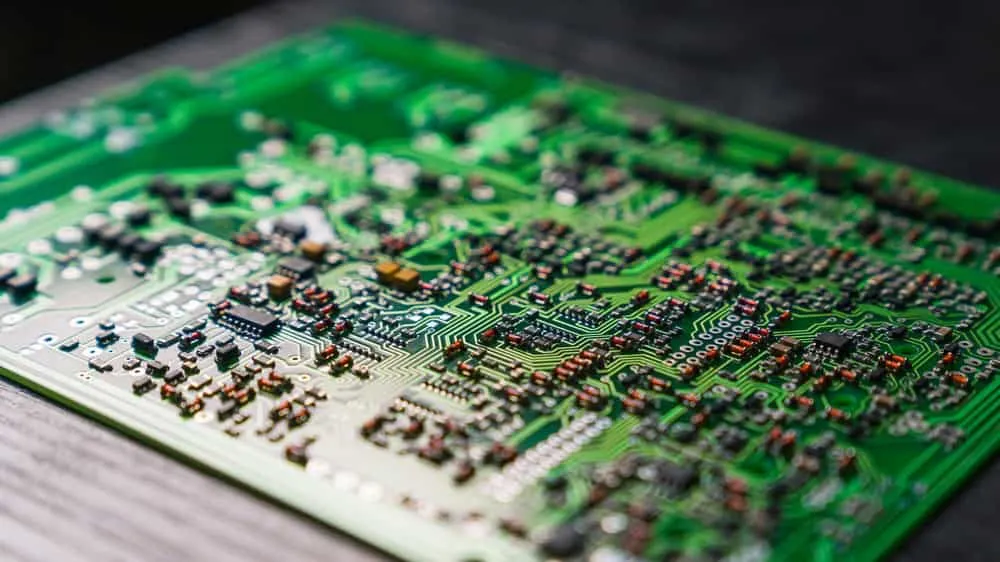

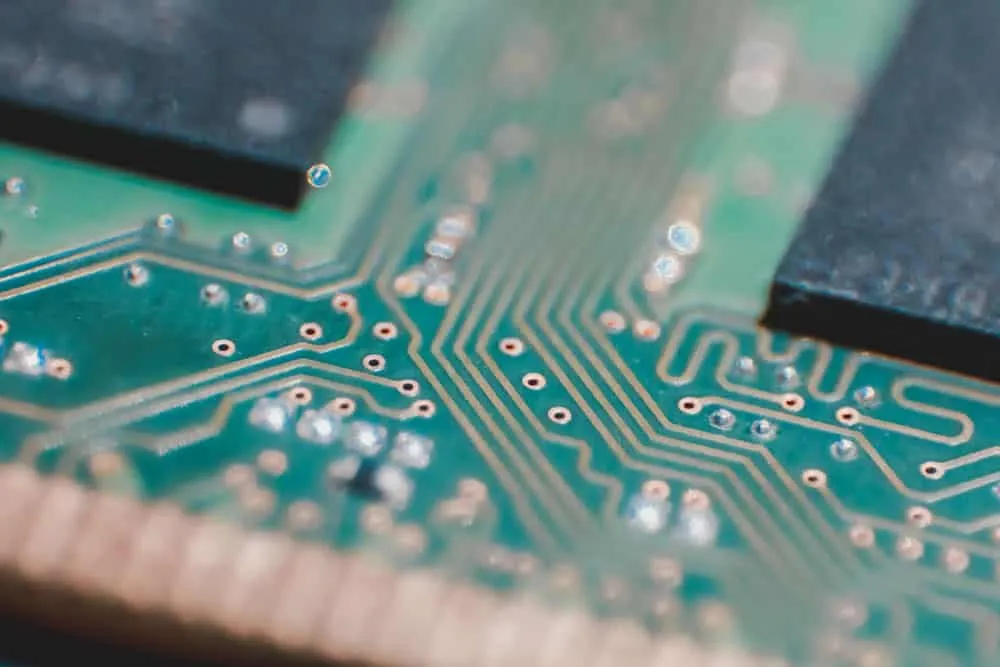

PCB assembly is as delicate of a process as circuit board fabrication. So assemblers need high-tech PCB assembly machine to mount and weld components on the board to make the circuit function as required.

The assembly process has several stages, and each one needs several devices. We’ll categorize the machines by the PCB processes below, so read on to learn more!

Solder Paste Application

You need two machines for the solder paste application step to weld SMT devices.

Solder Paste Printing Machine

Also known as a stencil printer, this machine applies solder paste to the PCB via a stencil screen. The paste, a gray-colored slimy substance, contains flux and tiny metal-alloy balls.

The machine fixes the PCB and stencil in position before applying the paste to ensure precise application.

Solder Paste Inspection Machine

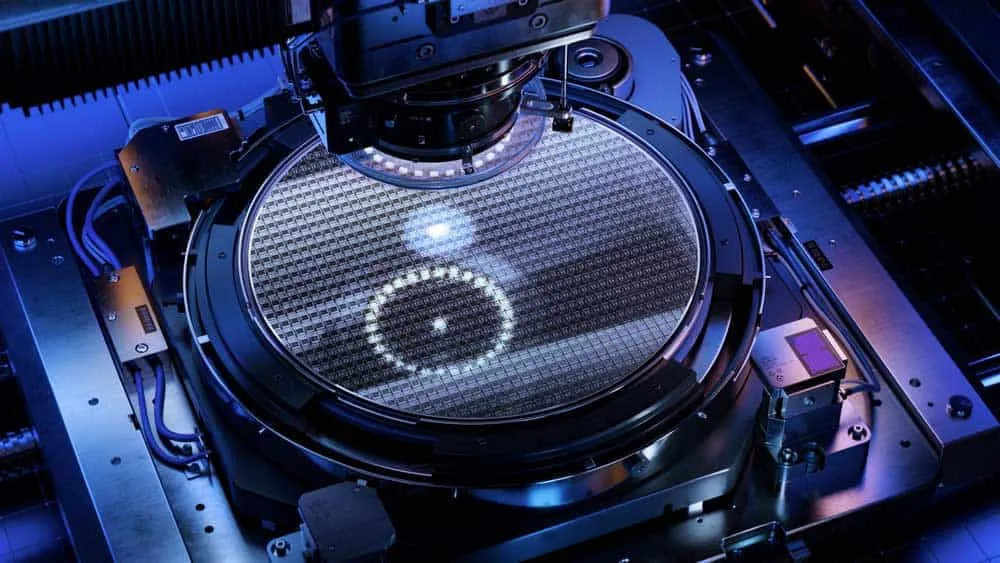

Although the paste printing process has the element of high precision, you need a solder paste inspection machine to detect errors.

Roughly 70% of surface-mount technology issues arise from inaccurate or substandard solder paste applications. So the inspection is necessary, especially in producing higher volumes of PCBs to reduce rework.

The machine uses cameras to capture high-resolution 3D images to assess factors like solder height, volume, and alignment. If it detects any issues, it will raise an alert.

Electronic Component Placement

The PCB heads to the automated component placement step after the precise solder paste application. This process requires the following machines.

Glue Dispensing Machine

Before surface-mount component placement, you need adhesive to hold the parts during soldering. This machine dispenses tiny glue dots on the board where the electronic components will sit.

The glue holds the components in place until the contacts get soldered to the pads. And if the board has thru-hole parts, the adhesive will secure them until the pins/leads get soldered.

Wave soldering for thru-hole components applies more pressure to the leads and can push the pieces out of place. So this glue is especially vital for thru-hole parts.

Pick-and-Place Machine

Also known as a surface-mount machine, this equipment picks SMT components from their packages, then places them above the applied solder paste.

Older placement methods were manual, and this process transitioned from manual pick-and-place machines to semi-automatic to automatic.

For through-hole component insertion, the process can be manual or require robots.

Soldering

After placing the components, use these machines to complete the soldering process.

Reflow Oven

Reflow soldering machines are ovens that heat and melt the solder paste under SMT components.

The machines also have conveyor belts for moving boards through the different temperature zones.

Wave Soldering Machine

It is impossible to solder through hole components using the solder reflow method; the molten solder will flow through the holes. The best way to weld these parts is using a wave soldering machine.

The device contains a bath of molten solder, which it agitates to create a wave of hot liquid. PCBs pass above the liquid metal at a height that the solder wave can contact the underside.

But these machines are becoming increasingly unpopular because the heat from the molten solder can damage sensitive surface-mount components. So assemblers have transitioned to selective soldering.

Selective Soldering Machine

Selective soldering only welds specific spots on the board that require through-hole assembly. Assemblers have the option of using either of the following.

- - Selective aperture tools

- Selective dip solder fountains

- Laser soldering machines

- Robotic soldering irons

- Hot gas induction soldering

- Miniature wave solder fountains

Solder Pot

Solvent Cleaning Equipment

Although machines apply solder paste and control the soldering process, it is not always neat. Excess solder and flux can remain on the surface.

Flux is acidic and can corrode the board. On the other hand, excess solder can create unwanted connections, leading to short-circuiting.

Solvent cleaners remove these elements immediately after soldering to prevent damage later.

Conveyors and Handling Equipment

These machines enhance production efficiency and cut costs along the assembly line.

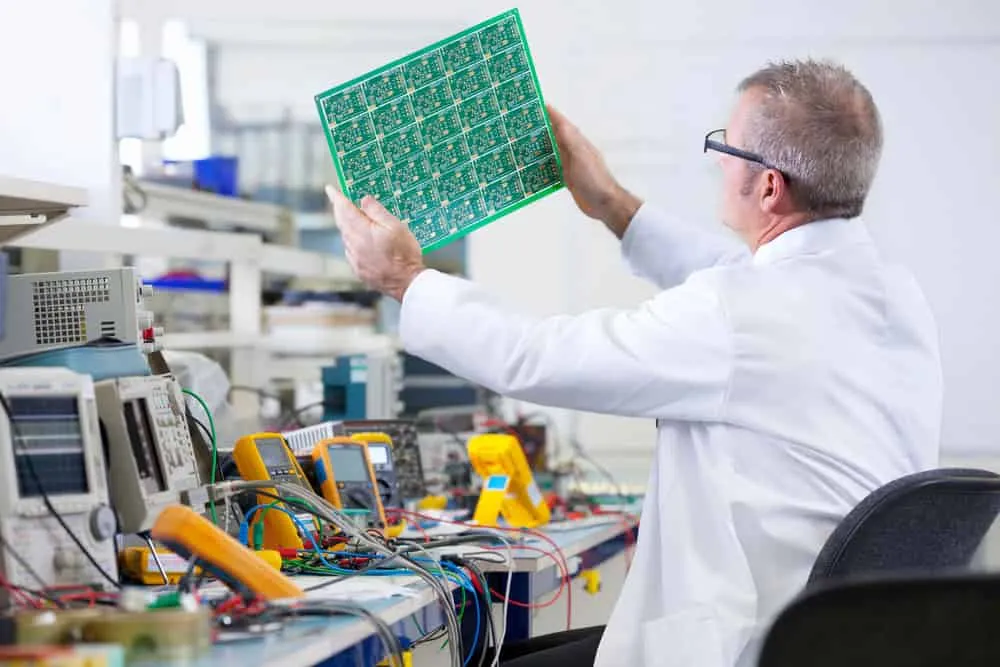

Inspection Machines

Inspection machines check the assembled boards to determine if they meet the customer’s requirements and assembly standards. They include the following.

Automated Optical Inspection Machine

Manual inspection using your eyes won’t cut it for modern PCB assemblies. Plus, it is slow. So AOI machines are necessary for mass production inspection to ensure consistent quality.

So the machine can detect missing components, incorrect positioning, scratches, shorts, and other defects.

In-Circuit Testing (ICT) Machine

Also known as the bed of nails test, ICT testing involves using multiple spring-loaded pogo pins to inject current and test the board’s functionality.

Each board gets placed above the “bed of nails, where the pin positioning matches PCB contact points.

The board reliably contacts the pins for test signal transmission when pressed down. So if there are any shorts or discontinuities, the machine will find them.

The pogo pins are sharp and can create tiny dimples on the solder joints. So you might notice these dents on the board on delivery, and should be no cause for alarm.

Functional Validation Test (FVT) Equipment

These machines determine if the PCBs are good enough for shipping to the client because they load firmware into the board’s chip. After that, they check if the PCB functions as it should for its respective application.

One of the most popular functional tests is the hot mock-up, which simulates the operational environment of the end product.

Rework Machine

If you detect faults when testing the boards, you need to repair the specific sections using rework stations.

Coating Equipment

This process is not compulsory for all circuit boards, but it protects the circuits from environmental factors like dust and moisture. It requires these two machines.

Conformal Coating Machines

Conformal coating machines apply thin polymeric layers above printed circuit boards that conform to the board’s contours, hence the name.

Curing Machines

This machine takes over after conformal coating application to cure the polymeric layer. Hot-air curing machines are typical in the industry, but their UV counterparts have the fastest curing times.

Wrap Up

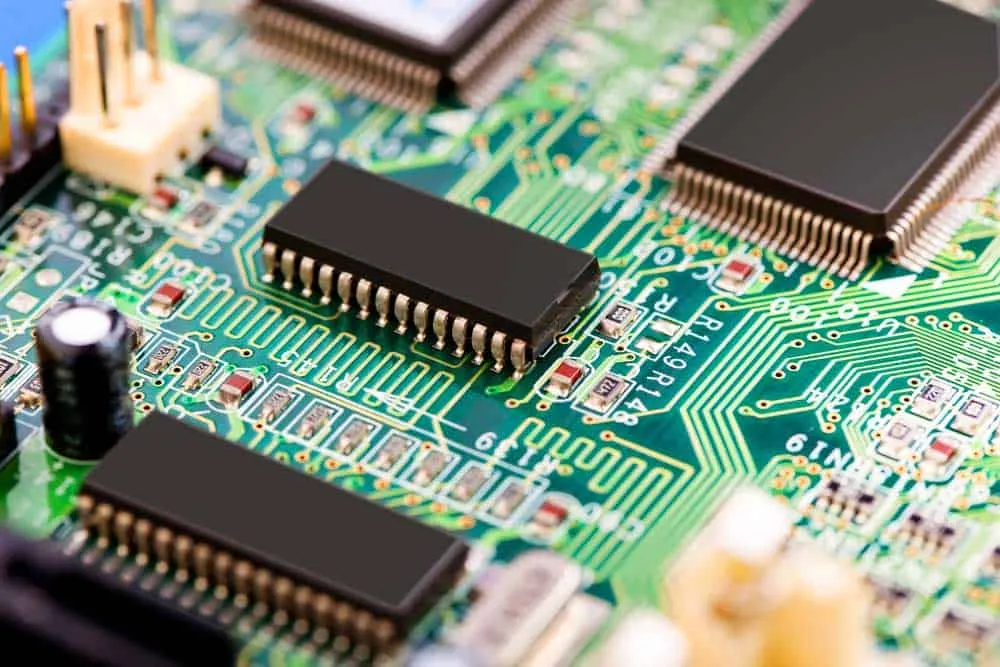

As you can see, the assembly process involves multiple steps, and each stage requires at least one piece of assembly equipment.

So you should set aside a significant sum to build a PCB assembly line. Or you can contact us to assemble your boards because we have all these machines.

So contact us today with your circuit designs. We offer both PCB fabrication and assembly services at reasonable prices.

Related Articles

Continue exploring similar topics

What Is First Article Inspection?

What is a first article inspection? First article inspections are generally associated with consumer electronics, medical devices,

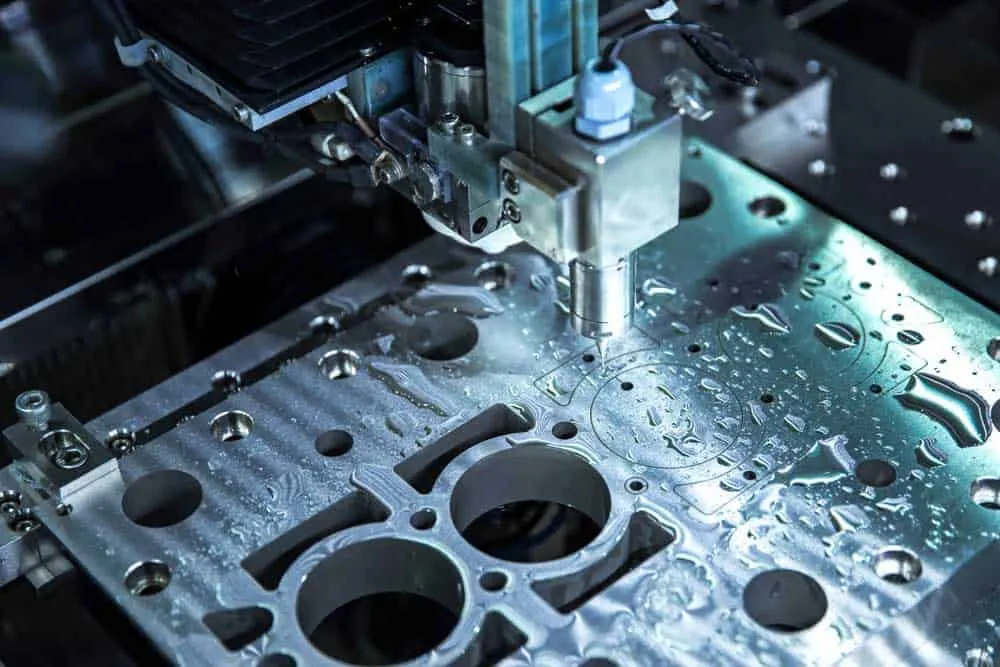

What is CNC Technology? Industrial Guide

Discover what CNC technology is and how computer numerical control revolutionizes manufacturing. Learn about CNC machining applications in electronics assembly and PCB production.

What is Ultrasonic Welding? Process Guide

Learn what ultrasonic welding is and how it uses high-frequency vibrations to join materials. Discover its applications in electronics, automotive, and medical industries.

Ready to bring your PCB design to life?

Get an instant quote for your custom PCB fabrication and assembly needs.

Get Instant Quote