How To Make a Plastic Injection Mold

This article is about how to make a plastic injection mold.Plastic injection molding is arguably the most efficient way to make plastic products.

This article is about how to make a plastic injection mold.

Plastic injection molding is arguably the most efficient way to make plastic products.

But the process must begin with a plastic injection mold, a component that defines the final product’s shape, size, and features.

So how to make a plastic injection mold, and how the molding machine works? Read on to learn more!

What Is a Plastic Injection Mold?

A plastic injection mold is a tool for making plastic products or parts from molten plastic. It usually consists of metal plates that lock to leave a cavity that matches the product design.

When molten plastic gets injected into the mold, it fills the cavity. Cooling solidifies the plastic, so you’ll get the final product when you open the mold plates.

Considering its definition, a plastic injection mold should do at least three functions.

- - Contain melted plastic without disintegrating

- Transfer heat

- Expel the cooled, molded parts

Plastic Injection Mold Structure

Plastic injection molds can have multiple components, but the basic structure consists of the following.

Mold Base

The mold base is the foundation block of a plastic injection mold. It is a rigid structure built using soft 718, P20, or S50C steel.

Mold Cavity

Mold cavities determine the size and shape of the final product. And since they handle all the heat, they have walls made of hardened steel.

Core Insert

While the mold cavity forms the external shape of the plastic part, the core insert forms the internal shape. It can also determine some of the product’s features.

And since it will be in molten plastic, this piece also needs to withstand the brunt of the heat. So it must have a durable and reliable construction.

Sprue and Runners

The molten plastic moves through a system of sprue and runners when injected into the system to get to the mold cavity.

Gates

Molten plastic gets into the cavity via gates. So the material flow into the mold begins at this point. And the gate size and shape affect the product quality.

These gates come in different types, including.

- - Pinpoint gate

- Side gate

- Submarine gate

- Direct gate

The gate type depends on the plastic material or the product’s size and shape. But it usually sits on the surface of the mold cavity to distribute the molten plastic evenly inside.

Cooling System

Cooling systems are like radiators. They run cooling fluids through channels around the mold cavity to solidify the plastic.

This system affects the production time of the injection molding process, so the faster it is, the better.

An efficient cooling system will enable you to make multiple molds per hour or day.

Ejection System

How To Make a Plastic Injection Mold

As you can see, plastic injection molds can be complicated tools because their structures contain multiple parts. So to make them, you must first come up with a design.

Design the Mold Using CAD Software

Determine the CAD software to use first. The design steps might differ depending on the application, but the workflow is usually the same.

Begin by molding the halves of the core moving outwards. When designing the cavity, check if the plates intersect fully with the molten plastic injection inlet.

Also, turn the visibility of the current mold core on and off for both sides. This switching will enable you to check the intersection with the other half mold core’s inlet.

Once done, export the mold for 3D printing or CNC machining.

3D Print or Machine The Mold

Let’s focus on the core insert and mold cavity. Whether you select CNC machining or 3D printing, use a hardened material that can withstand the melting temperature range of plastic. We recommend using hardened steel.

Which Types of Plastic Can You Use for Injection Molding

We categorize plastics into two types when thinking about injection molding. These are thermoset and thermoplastic materials.

These raw material plastics come as pellets. And you can mix them with recycled materials, colorants, or glitter, depending on the project.

Typical thermoplastics include the following.

Polycarbonates

These transparent thermoplastics can withstand high deformation levels and impact without cracking or breaking.

So you can use them to build medical devices, eyewear lenses, bulletproof glasses, etc.

Polypropylene

Acrylonitrile Butadiene Styrene (ABS)

Unlike polypropylene, ABS is a stiff material. But it is lightweight. So manufacturers usually use it to make toys.

Polyethylene

Polyethylene is suitable for making plastic bags and containers because it has high:

- - Tensile strength

- Ductility

- Impact resistance

Nylon

Nylon is rugged and has superb electrical insulation properties. So it is common in industrial plastic components, wires, and sports equipment.

How a Plastic Injection Molding Machine Works

As stated earlier, the plastic raw materials come as pellets. So the first step is melting them before injection.

Manufacturers usually use a barrel (with an auger) to heat and inject the plastic under high pressure.

The closed mold sits at the front of the barrel, waiting for the melted plastic to flow in via the sprue.

Screwing the auger into the barrel pushes the molten plastic resins forward under pressure into the mold.

The pressure is necessary to ensure the plastic fills the entire cavity. After that, water flows through the cooling system to solidify the plastic, usually in less than 60 seconds.

Although the mold has smooth edges, the plastic item cannot pop out when you open the mold. So the ejection system pushes it out, leaving room for molding another product.

Why Use Plastic Injection Molding?

Injection molding has the following benefits compared to other methods of making plastic products.

Ideal for Mass Production

Plastic injection molding can take less than a minute to make one product. This short cycle time makes the manufacturing process suitable for high-volume production.

Can Build Complex Parts

Building the injection mold can be complex. But you can design it to produce complicated plastic parts that cut down the components required to assemble the final product.

Additionally, you can mold screwing or fastening features and your company’s logo directly into the item.

Low Wastage

Unlike subtractive manufacturing processes like CNC machining, this injection process does not cut away and waste the material.

Product Quality Consistency

If you have a high-quality mold, it won’t change. So you can make thousands of plastic components using the same mold in one day.

And the best part is the tool will maintain the final product’s quality, size, and shape. You only have to ensure the plastic you inject matches the required quality.

Low Production Costs

It is expensive to manufacture plastic injection molds, meaning the initial costs will be high.

But the manufacturing costs will be significantly lower over time. Plus, the process has low wastage and high recyclability.

So once you handle the tooling costs, the low operational costs will give you good returns on your investment.

Wrap Up

Plastic injection molding is a relatively straightforward plastic part manufacturing process. But making the injection mold is the challenging part.

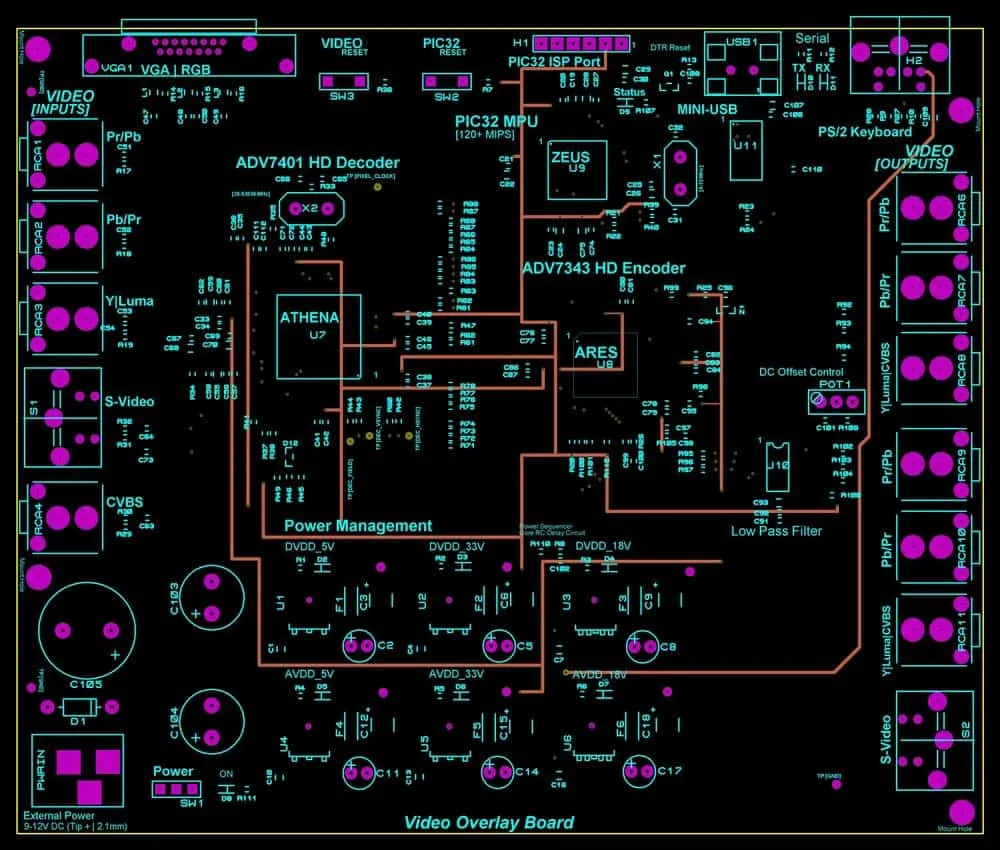

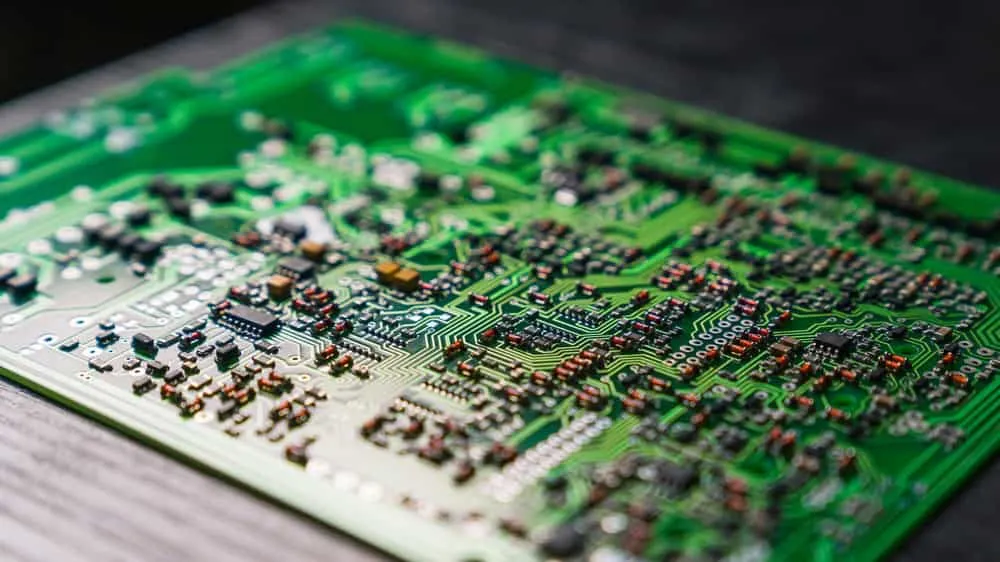

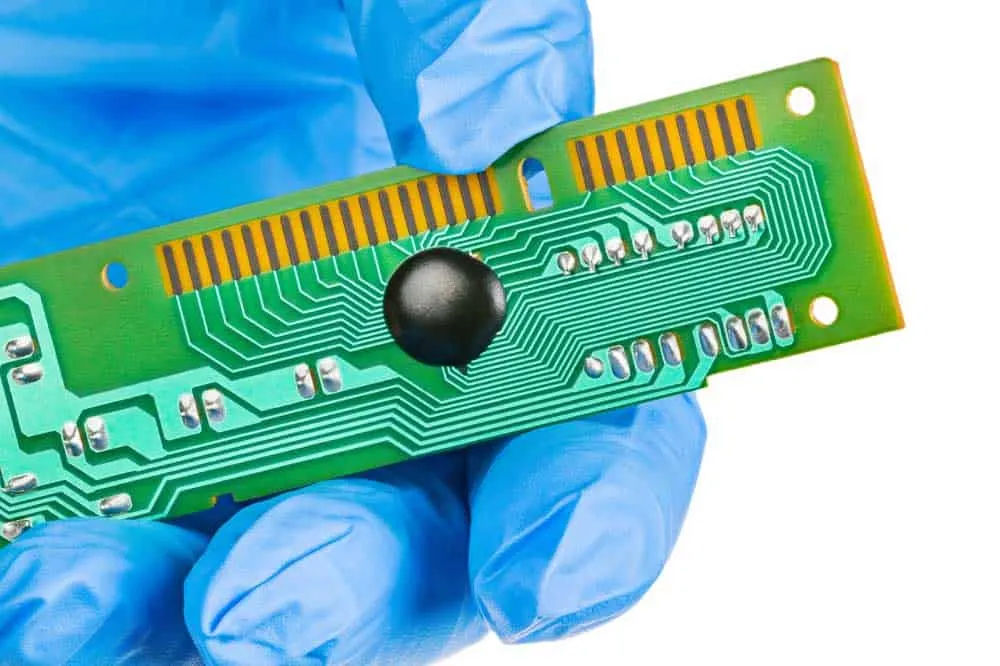

So take time to draw the design and build a prototype first to test the quality of the final product. And note the plastic types to use, plus their recommended applications. Need enclosures for your PCBs? Explore our PCB assembly services and manufacturing capabilities.

Related Articles

Continue exploring similar topics

How to Identify Diodes

Learn how to identify diodes by type and polarity. Understand markings, use multimeter testing, and recognize common diode types for your electronic projects.

How to Solder Wires to a Circuit Board

Do you know how to solder wires to a circuit board? It is straightforward, but you must perform it correctly to ensure a perfect electrical connection.

How To Mix Ferric Chloride for Etching

Learn how to mix ferric chloride for PCB etching. Get the right ratios, safety tips, and step-by-step instructions for etching copper-clad boards at home.

Ready to bring your PCB design to life?

Get an instant quote for your custom PCB fabrication and assembly needs.

Get Instant Quote