Hot Swap vs. Solder PCB Keyboards

This article is about hot swap vs. solder PCB.When building a custom mechanical keyboard, the primary component to consider is the PCB.

This article is about hot swap vs. solder PCB.

When building a custom mechanical keyboard, the primary component to consider is the PCB. And you can pick either from a hot swap or solder circuit board.

Both have pros and cons, so let’s compare hot swap vs. solder PCBs to see which wins.

What Is a Hot Swap PCB?

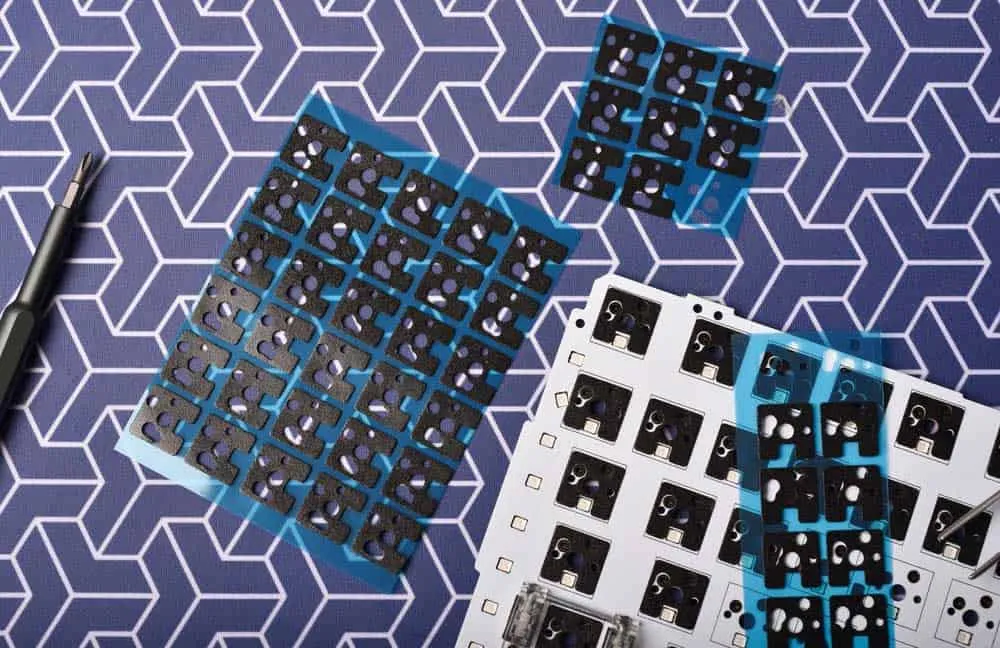

A hot swap PCB is a mechanical keyboard circuit board with pre-installed sockets for holding the mechanical switches.

So you only have to push the switch pins into these sockets, then mount the keys above them.

The purpose of hot-swap PCBs is to simplify the assembly of custom keyboards.

But when mounting the switches, you need to align them perfectly with the socket to avoid breaking the metal pins during insertion.

And these switches should have a soft surface for comfortable pushing. If plucking them from the board, be gentle to avoid damage to the sockets.

Pros of Hot Swap PCBs

- - Easy installation: One of the best advantages of hot-swappable keyboards is the ease of installation. You only have to align the pins and push the switch in. Removal is also a piece of cake.

- Beginner friendly: As a beginner with no soldering skills, you can try out multiple switches seamlessly to customize the keyboard.

- Easy to maintain: Your keyboard switches might require relubrication to smoothen the keypresses. The hot swap board simplifies this process because removing these switches is easy.

- Easy to tune: Keyboard stabilizers keep large keys from wobbling when pressed. And they might need re-tuning to eliminate emerging wobbles. In most cases, you have to disassemble the board for this process. And hot swapping makes things easier.

Cons of Hot Swap PCBs

- - Single layout: Most hot swap PCBs have a single layout. Some might give you more options, but not at the scale of solder PCBs.

- Impossible to do half-plate builds: Attempting half-plate hot swap PCB setups will leave some parts suspended, which can damage the board.

- Not as stable as solder PCBs: Inserting switch pins into hole sockets is convenient, but the holes don’t provide high mechanical strength. So the pins can come out if you handle the keyboard roughly.

What Is a Solder PCB?

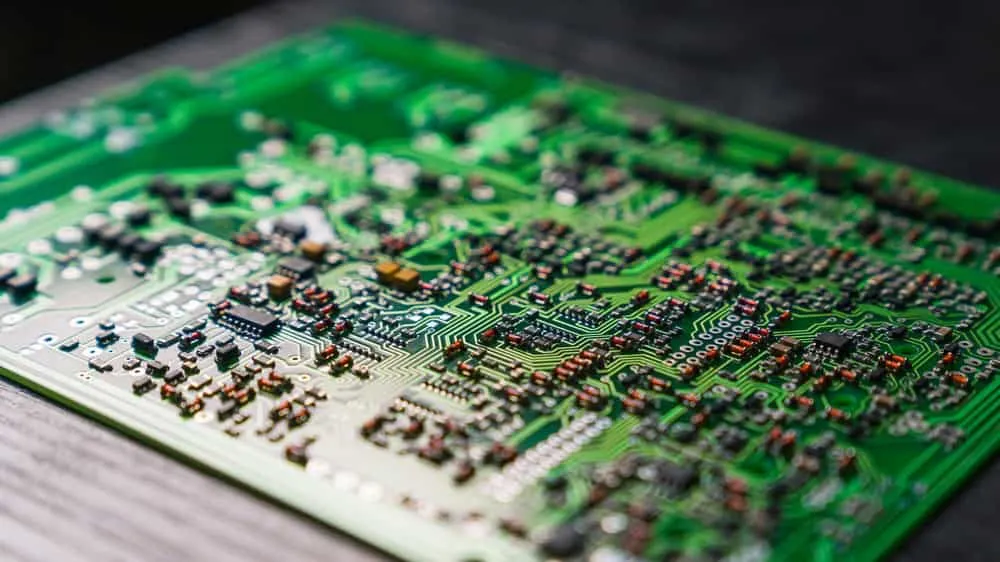

As the name suggests, a solder PCB requires solder and a soldering tool to attach the mechanical switch pins to the circuit board.

The process also requires perfect alignment, but the risk of breaking pins is lower.

Pros of Solder PCBs

- - Multiple layout options: One of the best advantages of solder PCBs is their customizable layout options. Since you don’t rely on pre-built sockets, you can solder individual switches to create unique layouts.

- Allows half-plate builds: You can use a half plate on these boards, which leaves the alphabet keys hanging and exposed. So when typing using these keys, they’ll be above the PCB, creating a soft key press. Flex cuts make the typing experience even smoother.

- Low cost: Solder PCBs are usually cheaper than hot-swap PCBs. But the margin is small (about $10). So if you are on a budget, this point is worth noting.

- Stable: Soldering has two functions: to create electrical and mechanical connections. The latter ensures the switches attach firmly to the PCB.

Cons of Solder PCBs

- Requires more to assemble: You need soldering tools, solder wire or paste, desoldering tools, and soldering skills.

- - Assembly requires more work and time: The process is not as simple as pushing switches into sockets.

- Challenging to customize: It is possible to customize solder PCBs, but it is an arduous process. You have to desolder the parts first.

- Difficult to maintain: You must disassemble the switches first to lubricate them later. The same applies to re-tuning the screw-in stabilizers.

Hot Swap vs. Solder PCB: Stability

One of the key differences between hot swap and solder PCBs is switch stability.

The latter offers more stability than the former because the solder joint provides mechanical strength.

Hot swap switches only slide into tight-fitting slots but can wobble because the joint is not permanent.

This issue brings about the durability factor. Soldered boards are indeed more durable than their hot-swap counterparts.

Soldering blocks any particles from getting between the key-and-metal contact point.

But dust and rust can get between the hot swap PCB-switch joint, affecting signal conductivity and increasing wobbling.

Hot Swap vs. Solder PCB: Installation and Removal

Mounting switches on solder PCBs requires soldering, a more complicated process than the simple insertion required in hot-swap boards.

And removal is challenging as well because you need desoldering tools.

So considering factors like lubing, tuning, and other maintenance processes, hot swap PCBs are easier to handle than solder boards.

Hot Swap vs. Solder PCB: Layout

If you have the required soldering skills and PCB knowledge, you can customize solder PCBs to have any layout.

For instance, you can mount a split backspace, a long 7u spacebar, a shorter 6.25u spacebar, etc. But you must know what you are doing to avoid damaging the board.

The Hot swap PCBs are not easy to modify because the switches must be compatible with the board.

Hot Swap vs. Solder PCB: Pins

Hot swap boards can be compatible with either 3-pin switches or 5-pin switches.

With solder PCBs, the switch type should also match the keyboard PCB. But regardless of the number of pins, solder joints are tight.

Are Hot Swap PCBs The Same?

Hot swap PCBs are becoming popular because you can customize them without soldering.

For instance, you can install backlit switches, rearrange them, or change the faulty ones easily.

But are they all the same? Most have similar features and layouts, except for one part: the switch or switch socket.

Some are 3-pin boards, while others have a 5-pin configuration. And the switch type can vary from soft (linear) to tactile and clicky.

So always check these factors before buying a hot swap keyboard PCB to enable you to make seamless customizations in the future.

Can You Convert a Solder PCB To a Hot Swap PCB?

You might have a preference for certain keyboard manufacturers. But what if they don’t offer hot swap boards?

However, attaching these sockets requires soldering. So you can pay for this one-time soldering or do it yourself, then enjoy the swapping flexibility later.

Wrap-Up: Which PCB Is Better

As you can see, hot-swap and solder PCBs have pros and cons. So the choice between them depends on your preferences.

Solder PCBs provide layout flexibility, stability, and even a half-plate build option.

But once soldered, it is challenging to do any modifications. So if you want to build a durable keyboard and are not into customization, use this board.

But if you want to modify the keyboard later, like adding a backlight under the keys, go for the hot swap PCB.

That’s it for this article. Comment below to let us know if you want a hot swap or solder PCB. For custom keyboard PCBs, check out our PCB manufacturing and prototype services.

Related Articles

Continue exploring similar topics

Tinning Flux vs Regular Flux

Today, we provide insights into the tinning flux vs. regular flux debate. We aim to educate you on their benefits to any typical soldering process.

SMD vs. SMT vs. THT: PCB Comparison

This article is a comparison of SMD vs. SMT. vs. THT.If you have researched the PCB assembly processes,

Allegro vs. Altium: PCB Software Guide

Allegro vs. Altium: Compare features, pros, cons, and pricing of these leading PCB design tools. Find out which software best fits your design needs.

Ready to bring your PCB design to life?

Get an instant quote for your custom PCB fabrication and assembly needs.

Get Instant Quote